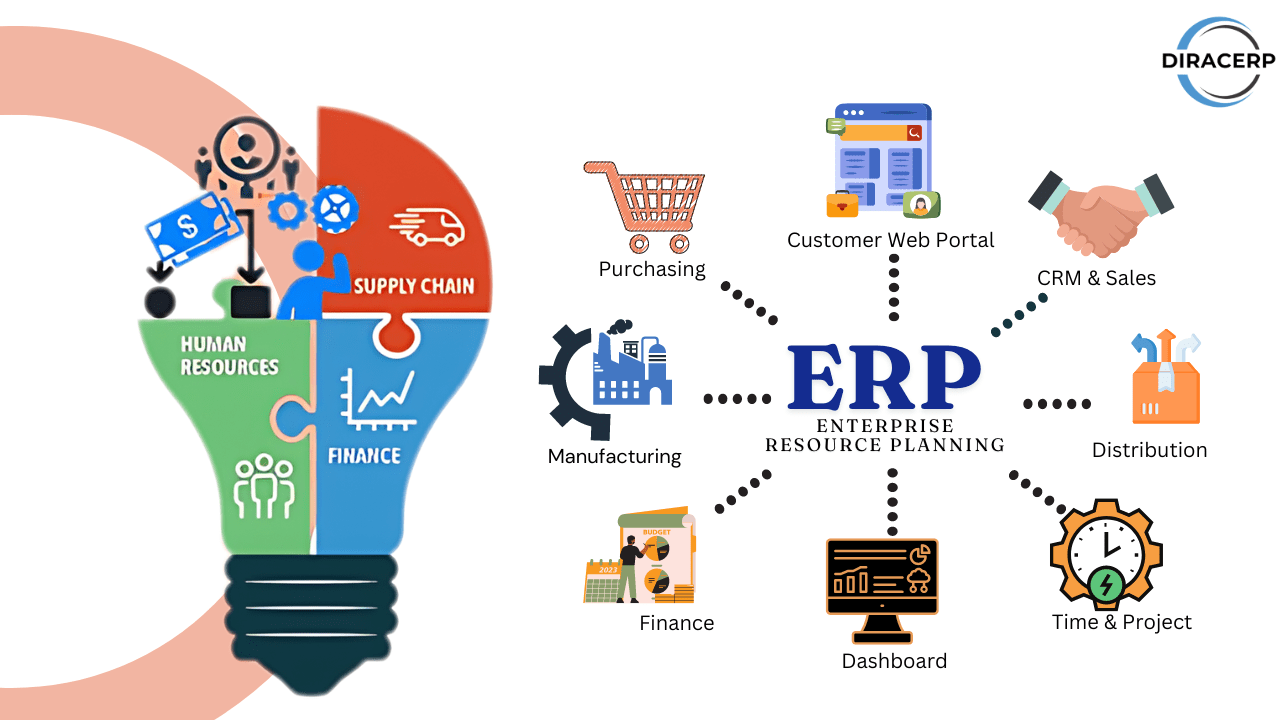

The COVID-19 pandemic has compelled manufacturers to quickly adapt to a new reality. This shift has underscored the critical role of ERP systems in maintaining business continuity under unprecedented conditions. While ERP’s value in mitigating abrupt changes has always been acknowledged, the pandemic has highlighted its vital role in ensuring operational stability on a global scale.

ERP systems, such as those provided by DiracERP, have proven essential in keeping industries functional through remote access, automated reporting, electronic data exchange, and real-time factory controls. These capabilities have never been more critical, as ERP solutions now play a pivotal role in sustaining manufacturing operations worldwide.

Sustaining Manufacturing Amidst a Global Pandemic

Key Contributions of ERP Systems During COVID-19

1. Empowering Employees to Work from Home

With the need to minimize on-site personnel, ERP systems have enabled front office staff to work from home without disrupting business operations. For example, Sushil Udhyog, a leading manufacturer in Jodhpur, India, utilizes DiracERP to allow its employees to access their ERP system remotely. This access enables them to monitor job statuses, inventory, and order completion from their mobile devices, ensuring seamless operation and customer satisfaction even during the pandemic.

2. Keeping Production on Track

Managing factory floors remotely presents significant challenges. However, ERP systems minimize the number of on-site staff required by optimizing work schedules, material handling, and real-time equipment monitoring for output, quality, and maintenance issues. This real-time monitoring has become a critical tool for maintaining production continuity with minimal on-site workers.

3. Managing Shifts in Demand

The pandemic has caused sudden shifts in demand patterns. While some manufacturers have seen demand drop, others have experienced spikes. Companies like Dezaro ~ Decor & Furniture and Rishabh Handicraft have adapted by utilizing DiracERP to manage their operations efficiently, even launching new product lines, such as mask manufacturing, to meet changing market needs. ERP systems help businesses adapt to these fluctuations by streamlining raw material supplies, scheduling, and personnel management.

Looking Ahead: The Future of ERP Systems

Post-pandemic, businesses will return to more normal operations but will be fortified by the lessons learned during this period of remote work and maximized technology use. Manufacturers’ perception of ERP systems will evolve, recognizing them not only for profitability and customer service but also as essential tools for business continuity in the face of sudden changes. ERP solutions are now seen as indispensable safety nets, capable of responding to and overcoming unforeseen events.

ERP as a Catalyst for Recovery for SMEs

For midsize companies, ERP systems are crucial in navigating the challenges posed by COVID-19 and fueling recovery. The pandemic has necessitated significant changes across various business processes. To thrive in the next normal, companies must focus on resilience, agility, and instant insight, moving beyond traditional practices designed for scalability and cost savings.

Cloud-based ERP solutions, like those offered by DiracERP, provide the flexibility needed to scale operations and respond to market fluctuations. For instance, BASANT Industries leveraged DiracERP to digitize their end-to-end processes, enhancing decision-making, standardizing workflows, and improving productivity through data analytics.

Implementing cloud-based ERP systems offers midsize companies the transparency needed to understand their performance, identify opportunities and risks, and manage inventory effectively. This level of insight is crucial for surviving disruptions, expanding into new markets, and accelerating growth.

ERP systems are more than just technology; they are enablers that help businesses adapt to change, optimize operations, and ensure long-term success.